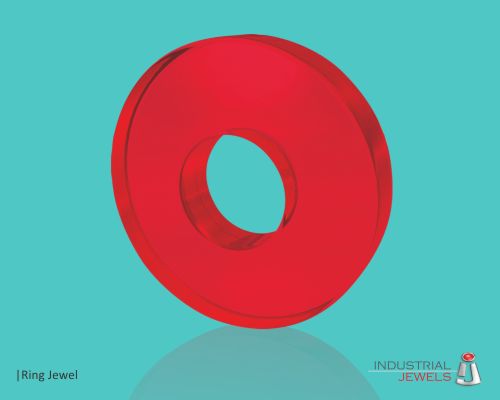

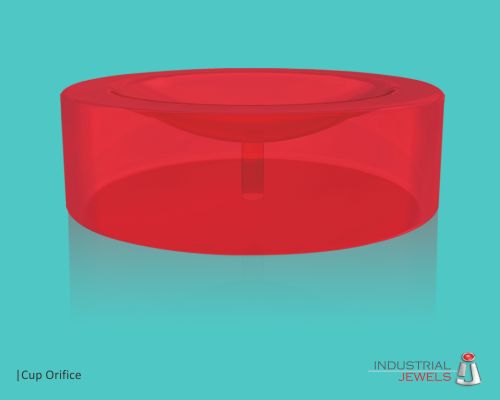

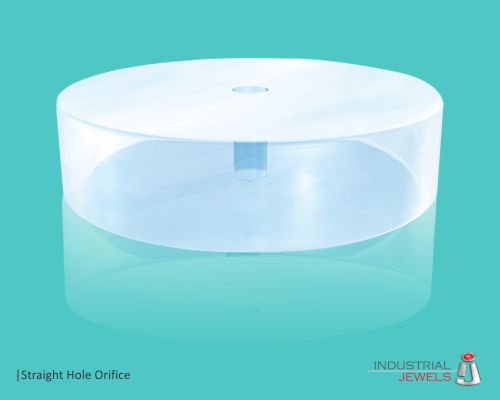

We specialize in making sapphire nozzle with perfect geometry and excellent surface finish to achieve optimum performance and lifetime.

Sapphire nozzle is commonly used in applications like water jet cutting where pure water at 5000 bars of pressure is used to create a laminar water jet for cutting various kinds of materials like metals, wood, fabrics, leather, glass and a variety of other materials. Industrial jewels manufacture water jet sapphire nozzles in hole size starting from 0.10mm.

The sapphire material used by industrial jewels is compliance to ROHS standard and is very well accepted for medical devices and analytical industry.

Sapphire material is a colourless single-crystal made by melting highly pure alumina under a flame fusion process. The material has a rhombohedral hexagonal structure. The hardness of sapphire is 9 on the MOHS scale compared to 10 of a diamond. As this single crystal is very hard we are able to polish it to a surface finish of 0,025µm.

High-pressure cleaning is used for paint scraping, concrete refurbishment, cleaning and maintenance of offshore equipment, ships and a wide variety of industrial cleaning.

A combination of the highly precise and controlled manufacturing process along with this super hard material makes the sapphire nozzle of industrial jewels a desired product in the market. The manufacturing process at industrial jewels is statistically controlled and monitored to ensure a highly reliable product which is checked at each step of manufacturing as per customer specified AQL levels.

The manufacturing facility at industrial jewels is located in Bhavnagar—India and certified with ISO 9001:2015 quality systems. The factory handles more than 1.6 million pcs on its production floor every single day. The plant is vertically integrated with 55 manufacturing operations under one roof.