Aperture wafers from ruby and sapphire are commonly used in inkjet printing for industrial application.

To have good quality inkjet printing, it is necessary to spray the ink in the right volume and flow quality. These aperture wafers perform their job flawlessly and are most suited for this application.

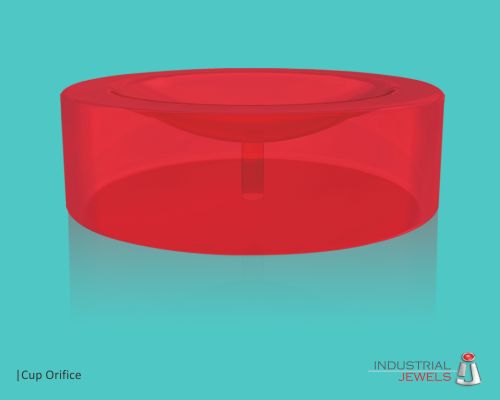

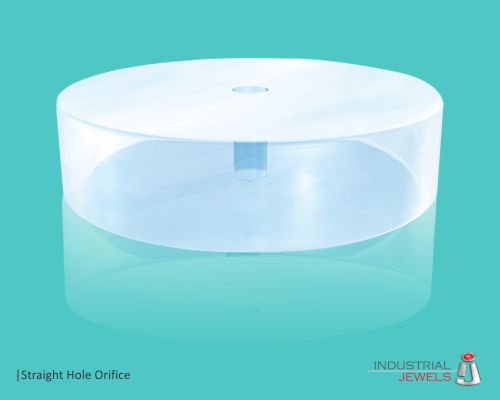

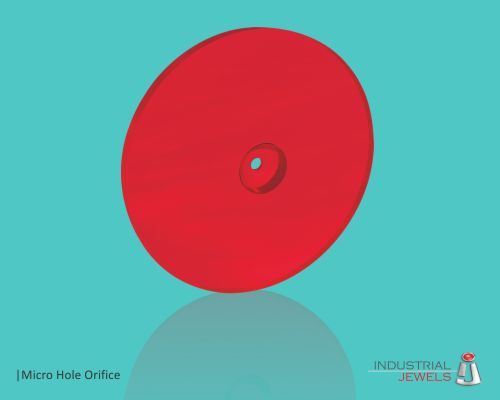

Industrial jewels specialize in manufacturing of aperture wafers from ruby and sapphire material. We manufacture aperture wafers with hole diameter starting from 0.06mm for inkjet printing and haematology.

For this application, it is necessary to have an ultra-precise hole and length to control the precise flow of fluid passing through it.

Ability to achieve these micron tolerances makes industrial jewels a preferred supplier on this market. Ruby and sapphire have extremely high chemical resistance and hence do not get affected with various fluids passing through them.

Ruby and sapphire are extremely hard to single crystal with more than 99% purity and ability to be polished to a very good surface finish. This ability to have a very good surface finish is an added advantage for this application. The fluids passing through the hole do not get deposited on the orifice surface resulting in precise dosing/ spraying.

We have been manufacturing these precise ruby and sapphire orifice with Swiss collaboration since 1966 and test them under critical conditions with precise Swiss measuring instruments. Our ruby and sapphire material are sourced from world-renowned European manufactures which ensure a stable and consistent quality.

At industrial jewels we employee 450 highly skilled people with an average employee relationship period of 18 years which ensure that the know-how and skills required to manufacture these precision parts are nurtured to meet the challenging demand of our growing customers. Today industrial jewels is a global leader in manufacturing micro precise parts from ultra-hard material and exports to more than 23 countries around the world to 180 customers.